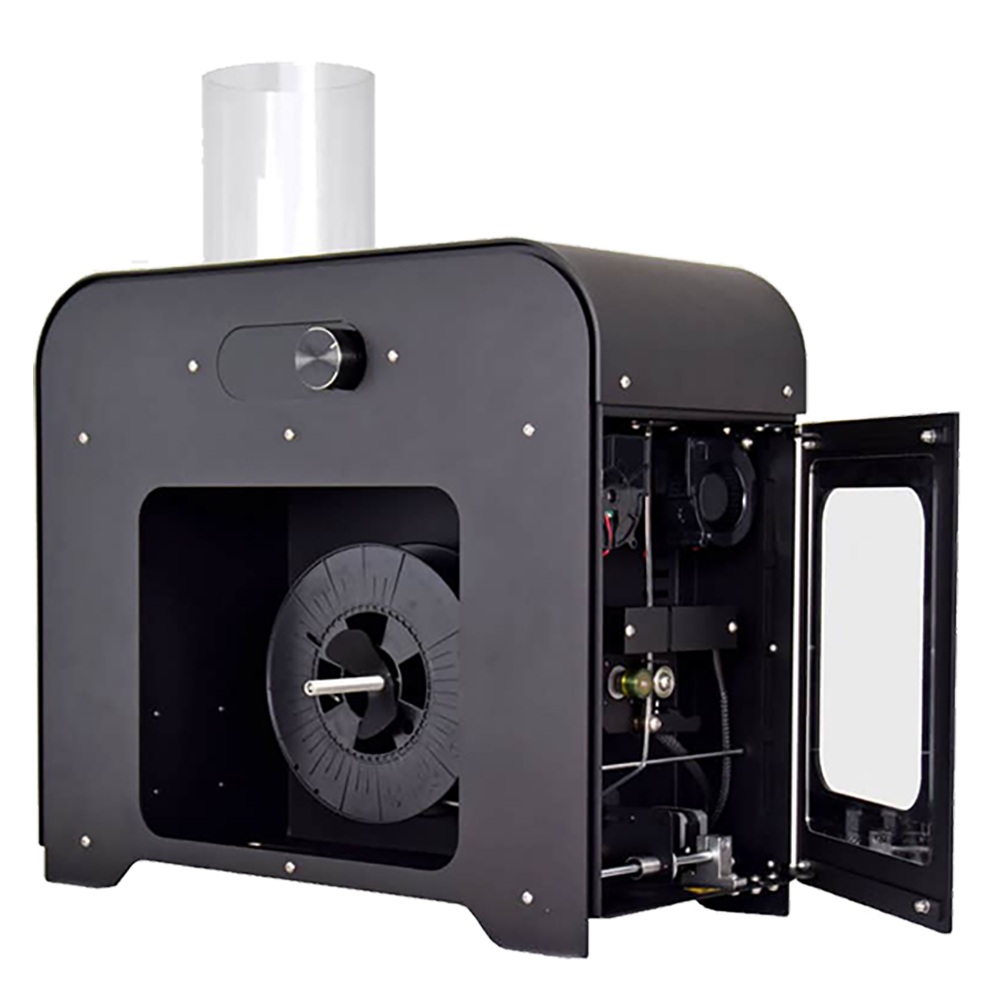

필라멘트 제조기

PRECISION FILAMENT MAKER ( 350 & 450 models )

PLA, ABS, PA12, PET, PETG, TPU, TPE 등과 같은 소비재의 압출 품질에서 업계를 선도하고 있습니다.

3devo의 Precision Screw가 장착되어 더 빠른 압출 속도와 안정적인 필라멘트 흐름을 제공하며 정확한 필라멘트 직경으로 생산이 가능합니다.

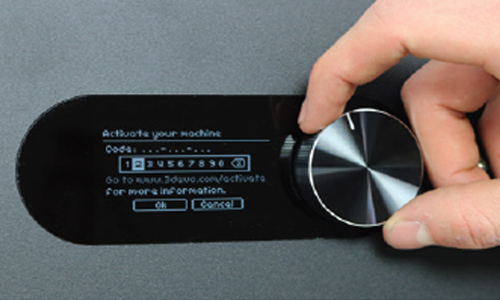

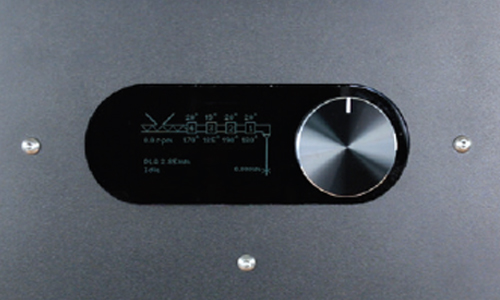

모든 사용자가 편리하게 사용 할 수 있도록 간단한 인터페이스와 재료별 파라메타 값이 입력되어 있습니다.

- 디스플레이 제어판

- 4개의 Heating Zone을 개별 제어 가능

- 기본적인 재료 설정값이 입력되어 있어 바로 사용이 가능

- 호퍼

- 호퍼 내부의 재료양을 확인하는 광학센서

- 내장형 안전그릴 사용

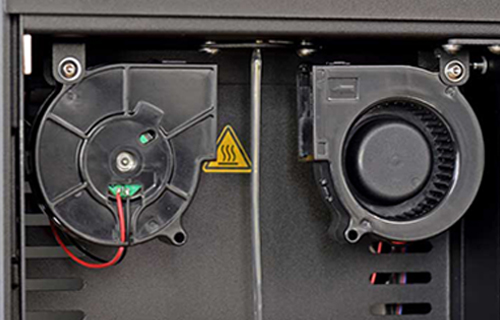

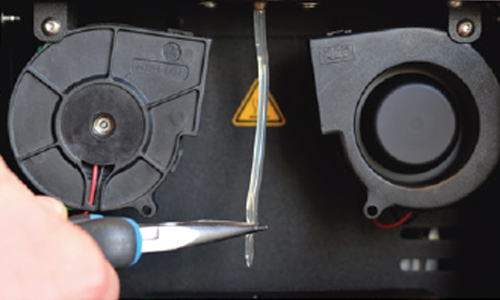

- 냉각 시스템

- 균일한 공기 분배를 위한 이중 팬 시스템

- 최적의 공기 흐름을 위한 팬 각도 조절가능

- 팬의 속도 조절 가능

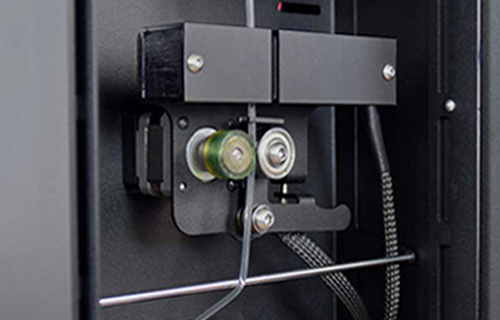

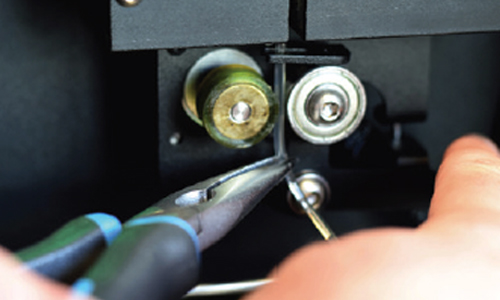

- 광센서+풀러시스템

- 0.5mm와 3.0mm 사이의 정확한 직경 측정

- 광학센서 적용으로 정확한 굵기와 진원도 보장

- 정확한 직경제어를 위한 자동속도 조정 가능

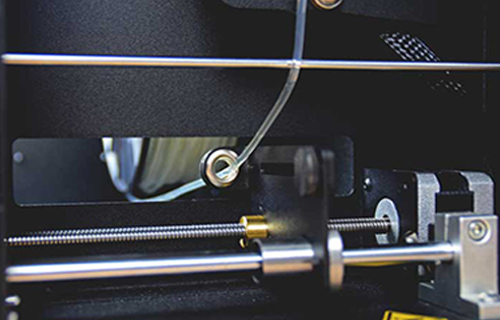

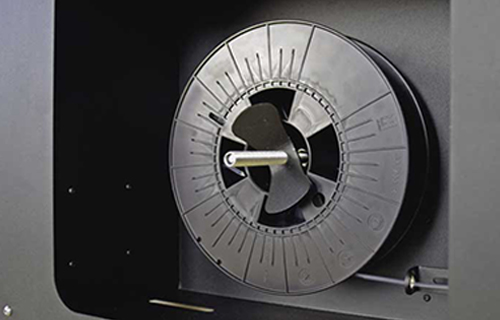

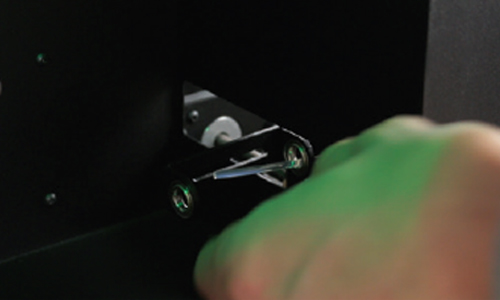

- 포지셔너

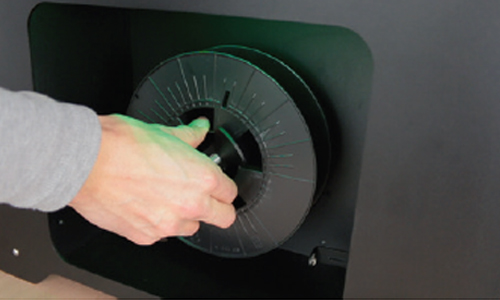

- 보빈의 크기를 설정하고 자동 스풀링이 가능

- 필라멘트가 엉키지 않고 깔끔하게 감김

- 포지셔너가 이동하며 보빈의 정확한 위치에 필라멘트를 감아 줌

- 호퍼

- 최대 직경 240mm, 너비 120mm 보빈까지 사용 가능

- 와인딩 작업시 장력 조절이 가능한 클러치 장착

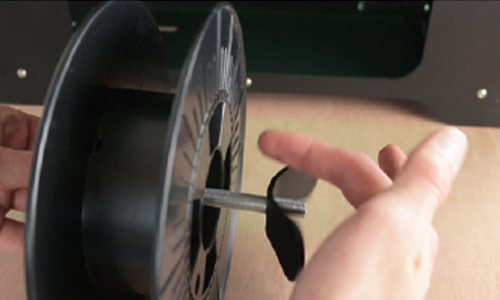

- 보빈의 빠른 교체를 위한 스풀 마운트 설계

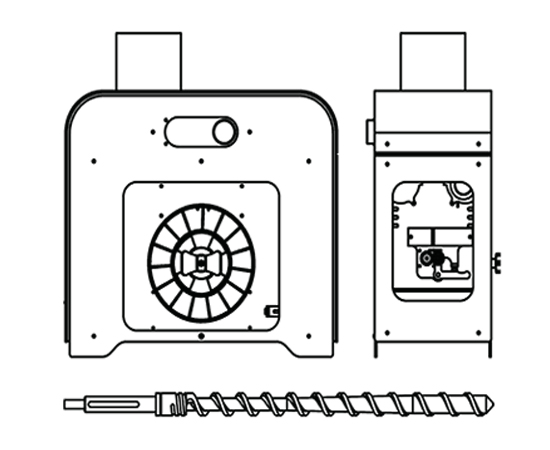

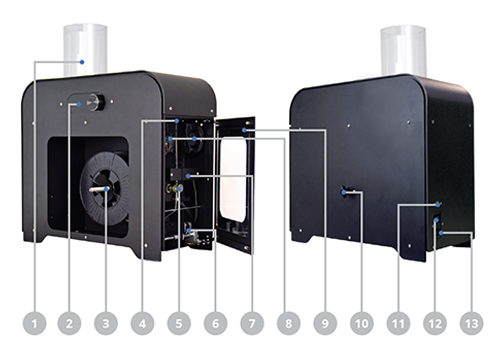

| Filament Maker Overview |

Temperature max. Band heater Heating zones Purpose Compatible materials Independent controls |

Max temperature of 350 °C Ceramic 4 For high-quality mass production PLA, ABS, PC, PS, PETG, TPU, TPE, PPS, PVA, Bio PE, NEW PET, and PA (6,12, 66) Yes |

| Output |

RPM range Filament diameter range Optical sensor accuracy Nozzle extruder |

2-15 RPM 0.5-3 mm (0.02-0.12 inches) 43 microns (1.69 mils) Diameter 4 mm (0.16 inches)- Replaceable |

| Extruder System |

Screw/Barrel alloy Hardening treatment Compression Extruder design Extrusion screw type |

High chromium and molybdenum steel alloy Nitrided 3 stage Swappable High-flow screw |

| Energy |

Consumption average Consumption max. Voltage Frequency |

300-400 W 1300 W 110-230 V 50-60 Hz |

| Capacity |

Hopper volume Spool holder Spool size |

2 liters 1 Diameter 240 mm (9.4 inches) Width 120 mm (4.7 inches) |

| Size & Weight |

Dimensions Weight |

506 x 216 x 448 mm 19.2 x 8.5 x 17.6 inches Extruder (Without box) 24.5 kg (54 lbs) Extruder + box 27 kg (59.5 lbs) |

| Connection |

Firmware updates Extrusion data analysis |

Regular updates DevoVision application |

| Filament Maker Overview |

Temperature max. Band heater Heating zones Purpose Compatible materials Independent controls |

Max temperature of 450 °C Ceramic 4 For high-quality mass production PLA, ABS, PC, PS, PETG, TPU, TPE, PPS, PVA, Bio PE, NEW PET, PA (6,12, 66), PEEK, PC, PS, PEKK, PAEK, PEI, PSU, PES, PTFE, PVD+, and many more Yes |

| Output |

RPM range Filament diameter range Optical sensor accuracy Nozzle extruder |

2-15 RPM 0.5-3 mm (0.02-0.12 inches) 43 microns (1.69 mils) Diameter 4 mm (0.16 inches)- Replaceable |

| Extruder System |

Screw/Barrel alloy Hardening treatment Compression Extruder design Extrusion screw type |

High chromium and molybdenum steel alloy Nitrided 3 stage Swappable High-flow screw |

| Energy |

Consumption average Consumption max. Voltage Frequency |

300-400 W 1300 W 110-230 V 50-60 Hz |

| Capacity |

Hopper volume Spool holder Spool size |

2 liters 1 Diameter 240 mm (9.4 inches) Width 120 mm (4.7 inches) |

| Size & Weight |

Dimensions Weight |

506 x 216 x 448 mm 19.2 x 8.5 x 17.6 inches Extruder (Without box) 24.5 kg (54 lbs) Extruder + box 27 kg (59.5 lbs) |

| Connection |

Firmware updates Extrusion data analysis |

Regular updates DevoVision application |

- What is in the box?

-

- Filament maker

- Hopper

- Spool holder

- 1x spool

- spool

- PLA granulate

- Devoclean mid-tempurature purge 180° - 320°

- USB cable

- Power cable

- Quick start or complete manual

- In this quick start you will find the essential instructions to set up your filament maker, right out of the box. For more detailed information about the functions and applications of the filament maker, you can visit our website: www.3devo.com/manuals

- What is where?

-

- Hopper

- User interface

- Spool holder

- Filament nozzle

- Puller

- Positioner

- Optical diameter sensor

- Filament cooling fans

- Door

- Winder slipper clutch

- USB port

- Power switch

- Power socket

- Warranty

- For information about the 3devo warranty policy visit: www.3devo.com/warranty

- Support

- For more information or technical support visit: www.3devo.com/support

- Quick start or complete manual

- In this quick start you will find the essential instructions to set up your filament maker, right out of the box. For more detailed information about the functions and applications of the filament maker, you can visit our website: www.3devo.com/manuals

- Remove the packaging

- Remove the top accessory box. Then remove the top foam blocks. Carefully place both arms beside the filament maker, lift it out of the box and place it on a flat surface. Remove the plastic cover bag from the filament maker. Finally remove and unpack the accessories from the spooling area.

- Set up your AIRID Polymer Dryer

1) Plug in the power cord and turn on the power switch at the back of the filament maker.

2) Press 'Activate' to unlock the full functionality of the machine. For more information go to.

3) Once you have read the information on the activation page, enter the code you have received in your e-mail and press 'Ok’.

4) Unwrap the hopper tube and place it on top of the extruder hopper.

5) Put PLA granulate in the hopper.

6) Take an empty spool and mount it on the spool holder.

7) Place spool holder with spool on the spooling axis.

8) Push the menu button and click "Start Extrusion" (with the PLA preset).

9) Main screen will indicate that the system is 'Heating. Wait about 10 minutes and the extrusion process will start automatically.

10) When the filament is extruding, wait until about 20cm is out of the nozzle.

11) Open the puller clamp, then pull the soft filament through the Optical diameter sensor and puller.

12) Go to "Start spooling" in the menu and follow the steps on the screen.

13) Cut the filament when the set size is reached and start spooling.

14) Guide the filament through the positioner holes.

15) Guide the filament through the spool (inhole).

16) Wait and watch as your first spool of PLA filament is made.

CS Center

토/일/공휴일 휴무

런치타임 : 12:00 ~ 13:00